404. That’s an error.

The requested URL was not found on this server.

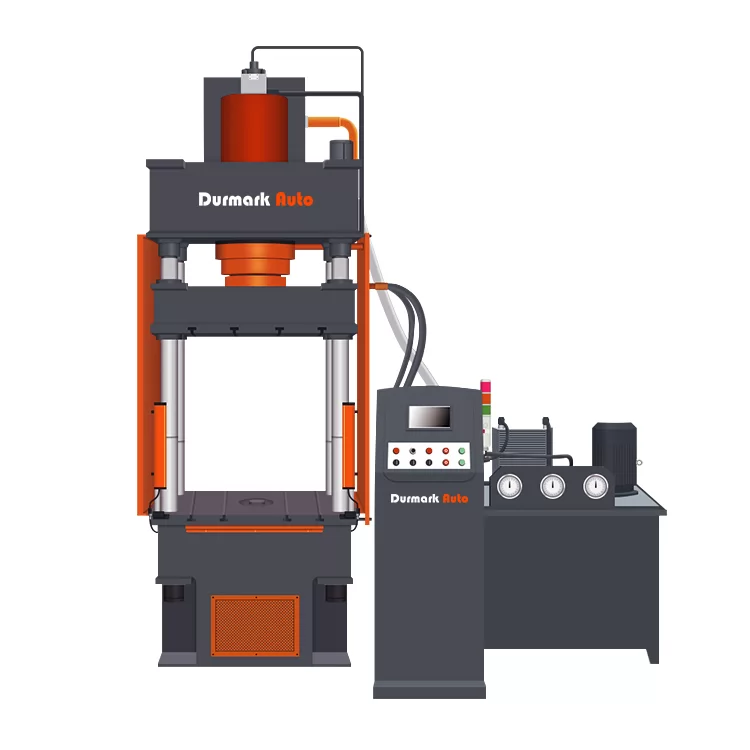

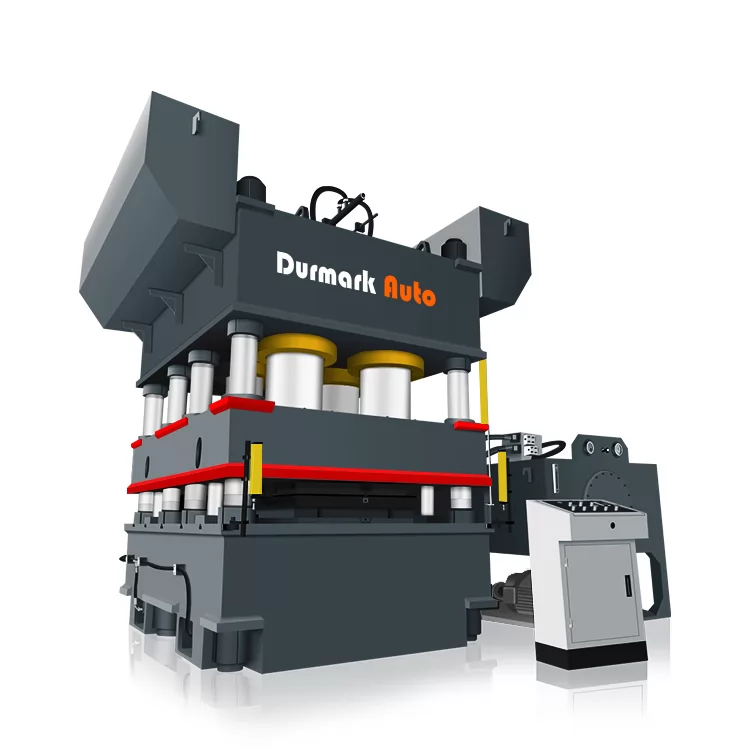

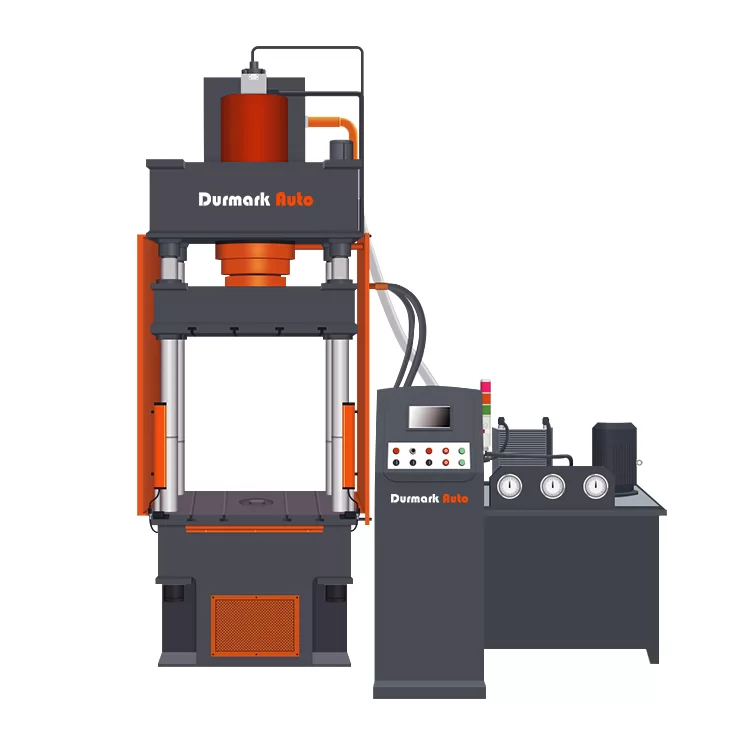

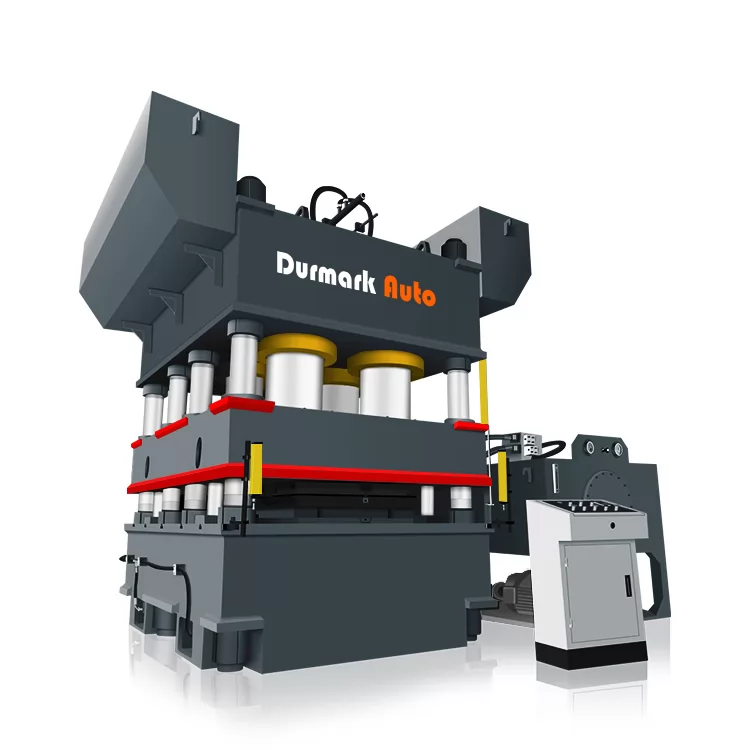

You May Like

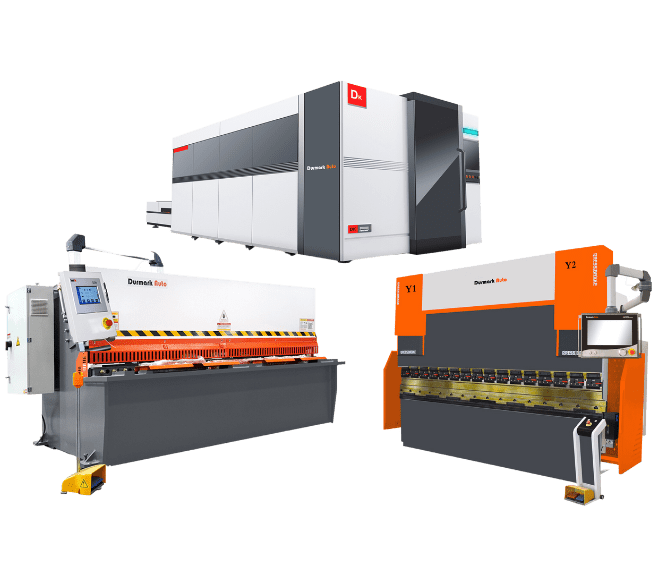

View all products

Talk to Our Expert About Your Needs

Durmark is a design, development, production and sales of an integrated company

-

Contact info

District, BoWang, MaAnShan City, Anhui, China

District, BoWang, MaAnShan City, Anhui, China

© 2023 Durmark

Marketing Support by Globalsir

.png)

.png)