Request a Quote

Request a Quote

Choosing the best hydraulic press brake manufacturer is vital for metal fabrication businesses seeking improved efficiency, precision, and long-term ROI. Reliable hydraulic press brake manufacturers offer high-quality machines with advanced CNC technology and excellent after-sales support. Whether buying your first press brake or upgrading, partnering with trusted manufacturers ensures enhanced production performance.

This guide helps you compare top hydraulic press brake manufacturers, evaluate key features, and make a smart, cost-effective investment. Start your search today to find the ideal hydraulic press brake for your fabrication needs.

Hydraulic press brakes are vital metal bending machines widely used in industries such as automotive, aerospace, and construction. These machines offer high precision, excellent repeatability, and superior efficiency, making them perfect for complex metal fabrication tasks. Featuring advanced CNC press brake controls, adjustable back gauges, and flexible tooling, hydraulic press brakes outperform manual and mechanical alternatives in accuracy and stability.

Choosing the best hydraulic press brake manufacturer guarantees durable equipment, consistent performance, and reduced downtime. Whether for small workshops or large factories, investing in a quality hydraulic press brake from a trusted supplier enhances productivity and ensures cost-effective operations.

A reliable hydraulic press brake manufacturer ensures consistent build quality using high-grade materials and precision components. This guarantees superior bending accuracy and long-term machine stability, critical for industrial applications demanding precision and durability.

The best press brake manufacturers incorporate advanced CNC automation systems. These enable precise control, improve production efficiency, and reduce human error, making them ideal for modern manufacturing environments seeking high productivity and accuracy.

Top hydraulic press brake suppliers comply with essential certifications like ISO and CE. These certifications validate product safety, environmental compliance, and manufacturing excellence, giving buyers confidence in the quality and reliability of the equipment.

A trusted hydraulic press brake manufacturer offers detailed technical documentation and professional operator training. This support ensures users can efficiently operate and maintain machines, minimizing downtime and enhancing overall productivity.

Reliable suppliers provide responsive after-sales support, including troubleshooting and spare parts availability. Strong customer service is vital for sustaining machine performance and supporting long-term operational success.

Clearly outline your production needs before choosing a hydraulic press brake supplier. Consider bending capacity, material types, and desired automation levels. This helps find a hydraulic press brake machine that fits your metal fabrication requirements, improving bending accuracy and operational efficiency.

Choose a hydraulic press brake manufacturer with strong industry experience and excellent customer feedback. Verified certifications and positive reviews indicate reliability. A reputable supplier guarantees quality hydraulic press brakes and dependable service, ensuring smooth operation and long-term satisfaction.

Opt for hydraulic press brakes equipped with advanced CNC control systems, durable hydraulic components, and up-to-date safety features. Modern hydraulic press brake technology enhances bending precision, increases productivity, and promotes workplace safety, making it essential for competitive metalworking operations.

Reliable after-sales service is crucial when selecting a hydraulic press brake manufacturer. Ensure the supplier provides timely spare parts, professional training, and responsive technical support. Strong after-sales support reduces downtime, extends machine lifespan, and maximizes productivity for your metal fabrication business.

Balance cost with quality when choosing a hydraulic press brake supplier. Avoid low-cost machines lacking durability. Focus on hydraulic press brake manufacturers offering high-performance equipment with a solid return on investment, ensuring efficiency and cost-effectiveness over the machine’s lifecycle.

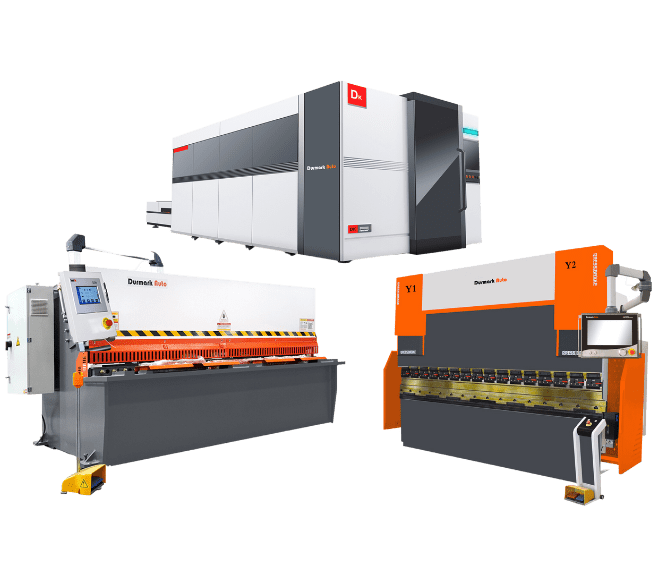

When selecting the best hydraulic press brake manufacturer, it’s essential to evaluate machine quality, advanced CNC technology, competitive pricing, and reliable after-sales support. Leading manufacturers such as Amada, Trumpf, Accurpress, and Durmark offer high-precision hydraulic press brakes known for durability and efficiency. Additionally, many reputable Chinese hydraulic press brake manufacturers provide cost-effective CNC press brakes with strong performance, ideal for various fabrication needs.

Whether you require a CNC hydraulic press brake, a customized automated system, or a standard model, comparing product features and pricing is key. Always review customer feedback, certifications, and global service networks to ensure your chosen hydraulic press brake manufacturer meets your production goals. Making an informed decision helps you stay within budget while maximizing long-term machine performance and reliability.

Choosing the best hydraulic press brake manufacturer is essential for businesses seeking precision, efficiency, and reliability. Leading hydraulic press brake manufacturers provide extensive customization options, including variable bending lengths, tonnage capacities, and specialized tooling solutions tailored to your unique production requirements. A trusted manufacturer delivers high-performance custom hydraulic press brake systems designed for flexibility and durability.

Integration with advanced CNC control systems, robotic automation, and ERP software ensures seamless operation and enhanced productivity. Many top manufacturers also offer intelligent automation solutions for large-scale fabrication processes. Selecting a manufacturer that excels in both customization and system integration empowers your facility to optimize workflow and maintain a competitive edge in today’s fast-evolving manufacturing landscape.

When selecting the best hydraulic press brake manufacturer, transparent pricing is crucial. A comprehensive, itemized quote should clearly outline machine cost, shipping fees, installation, operator training, and after-sales support—ensuring no hidden costs increase your total investment. While affordable hydraulic press brakes may appear tempting, it’s vital to focus on long-term ROI by assessing factors like machine durability, maintenance costs, and productivity gains.

Choosing a trusted hydraulic press brake manufacturer who delivers high-quality, reliable equipment often results in better value and improved operational efficiency. Prioritize overall cost-effectiveness and total lifecycle benefits rather than just the initial purchase price to maximize your hydraulic press brake investment returns and boost your facility’s workflow profitability.

Choosing the best hydraulic press brake manufacturer is key to achieving superior precision, production efficiency, and long-term machine reliability. Evaluate top hydraulic press brake brands based on technical capabilities, CNC control systems, after-sales support, and customization options to ensure the right fit for your business. Avoid low-quality alternatives that may compromise your operations. Instead, invest in proven hydraulic press brake solutions from trusted manufacturers. Whether you need a compact model or a high-tonnage CNC press brake, making the right decision today secures better ROI tomorrow.

Ready to upgrade your manufacturing line? Contact us now for expert guidance, tailored quotes, and a free consultation to find the ideal hydraulic press brake for your production needs.

.png)