Request a Quote

Request a Quote

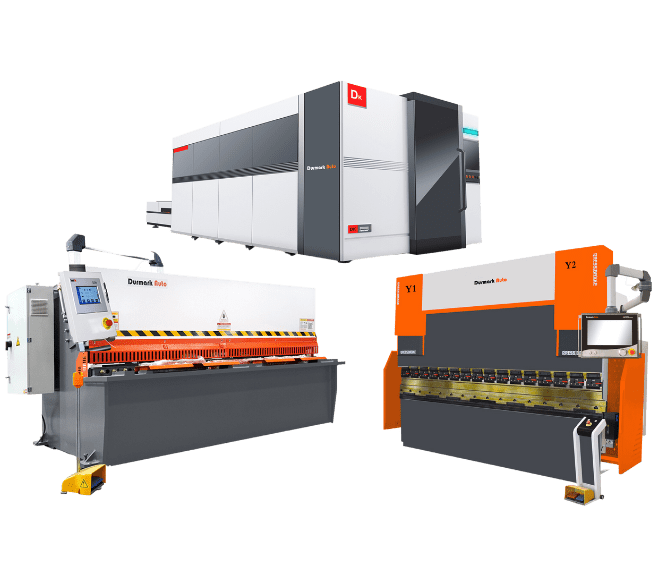

Why

Durmark

Where is your company located?

Our company is located in Ma anshan City, Anhui Province, only half an hour's drive from Nanjing Lukou Airport. If you visit our company, we will arrange a special car to pick you up at the airport.

Are you a factory or a trading company?

Our company is located in Ma anshan City, Anhui Province, only half an hour's drive from Nanjing Lukou Airport. If you visit our company, we will arrange a special car to pick you up at the airport.

What is the cost of the V-grooving Machine?

Although some customers may find it very expensive, these prices are not too expensive for the benefits created by using the sheet metal V-grooving Machine. Different specifications, different prices, please choose a good specification to contact us. The prices we sell are set according to the factory wholesale price, which is more competitive than other peers. If your budget is not a lot, then you can consider choosing a cheap industrial V-grooving Machine from us.

How to buy Industrial V-grooving Machine?

Consultation: After receiving your request, we will recommend the most suitable V-grooving Machine for you.

Quotation: We will provide you with a detailed quotation according to the consultation. You will get the most suitable specifications, best accessories and affordable prices.

Process evaluation: Both parties carefully evaluate all order details (specifications, technical parameters and business terms) to eliminate any misunderstandings.

Place an order: If you have no questions, we will send you a PI (proforma invoice). Then, we will sign a contract with you.

Production: We will arrange the brake production immediately after receiving your sales contract and deposit. The latest news about production will be updated during the production process and the buyer will be notified.

Quality control: The entire production process of the machine will be subject to regular inspections and strict quality control. The complete V-grooving Machines will be tested to ensure they work properly before leaving the factory.

Delivery: After the buyer confirms the brake, we will arrange the delivery according to the terms in the contract.

Customs clearance: We will provide the necessary transportation documents for the buyers who press the sheet metal V-grooving Machine and ensure smooth customs clearance.

Support and service: We will provide professional technical support and service by the brakes via telephone, email, Skype, WhatsApp, online real-time chat, and remote service. We also provide door-to-door service in some areas.

How long does it take to deliver the machine?

Durmark's delivery time is 15-20 days, and the goods are delivered strictly within the stipulated time.

What payment methods do you accept?

Generally, we acceptT/T, L/C, D/D and D/P payment. If you are our special customer, we can accept better payment methods.

How long is the warranty period of your machine?

For traditional machines, our warranty period is one year. For special non-standard machines, we may provide 2-3 years warranty, but it should be confirmed with our sales team in advance. During the warranty period, we provide free replacement parts.

Do you accept OEM customization?

Yes, we accept OEM customization, such as customized machine appearance, color, configuration, etc. Of course, the price of custom products is a bit higher. Please contact our sales team for details.Durmark Auto supports OEM or ODM customization and has provided OEM support to customers in Argentina, Russia, Canada, Australia, Philippines, Bangladesh, Kazakhstan, etc.

What is the minimum order quantity for your machine?

The minimum quantity we can accept is one, which can be customized by OEM according to your needs.

How do you ensure the quality of the machine?

Mainly control incoming inspection, production process, outgoing inspection and after-sales service to ensure the overall quality of products.

Quality control of incoming materials: full inspection, sampling inspection and batch inspection of all incoming raw materials and components. Distinguish defective products that do not meet the company's requirements, and make clear signs at the same time.

After the machine is completed, the precision is detected by advanced precision testing instruments, and the information is fed back in real time.

What kind of packaging does your machine use?

Since our machine is a large-scale equipment, it will be packed with rain-proof film and wooden box, directly into the container, and then fixed with steel wire, so that when the freighter is sailing at sea, the machine will not hit the inside of the container due to the swing of the ship , to ensure that the machine is intact. This container won't hold anything other than the machine you ordered.

How does your company provide after-sales service?

Dumark products are 30 years old and very mature for problem solving. In general, we can directly solve a lot of problems through video. For small problems during the use of the machine, we will arrange mechanical engineers to help you solve them remotely, and provide one-to-one guidance, such as sending text instructions or videos, to teach you how to solve the problem. If the part that needs to be replaced is within the warranty period, we will send it to you free of charge. Of course, you can also buy locally (if you can), which saves even more time. For more serious problems, if the way of remote guidance does not work, we will arrange engineer on-site service. In areas where there are agents, we will directly contact the agents to provide services.

Does your company provide training?

Does your company provide training? Yes, we support door-to-door installation, commissioning, training, maintenance, and repair services. Address all your concerns and questions.

Will your company provide relevant paper materials?

Certainly. Usually shipped with the machine, it also includes various manuals, operating instructions, precautions, circuit diagrams, hydraulic diagrams, etc.

Durmark is a well-known machinery company in China, with high-quality sheet metal machine, low prices, and decades of manufacturing and overseas sales experience. Our products will surely satisfy you. Contact us now to get the latest discounted price. Welcome to consult!