Request a Quote

Request a Quote

Choosing the right CNC press brake manufacturer is essential for improving metal forming efficiency, ensuring bending accuracy, and maintaining competitiveness in today’s manufacturing industry. With a wide range of CNC press brake machines available—differing in tonnage, control systems, and automation features—it's crucial to evaluate key factors before making a decision.

This comprehensive guide explores how to select the best CNC press brake based on precision, machine type, back gauge control, cost-effectiveness, and after-sales service. Whether you're upgrading existing equipment or investing in your first CNC press brake, understanding these elements will help you make a smart, long-term investment. Start optimizing your production today with the right CNC press brake solution.

CNC press brakes are essential in precision sheet metal fabrication, offering superior control and efficiency for complex bending tasks. Top CNC press brake manufacturers deliver advanced systems with high bending capacity, back gauge accuracy, and user-friendly CNC control interfaces. These machines are widely used across automotive, aerospace, and industrial manufacturing.

Choosing the right CNC press brake ensures consistent quality, reduces material waste, and improves production speed. To stay competitive, manufacturers must invest in reliable CNC press brake solutions that support evolving technology and long-term performance.

Bending Capacity: Match Your Material Needs

A CNC press brake’s bending capacity must align with your workload—consider the thickness, length, and material type. Leading CNC press brake manufacturers offer models tailored for mild steel, stainless steel, and aluminum. Choosing the right capacity ensures efficient forming and prevents machine overload or underutilization.

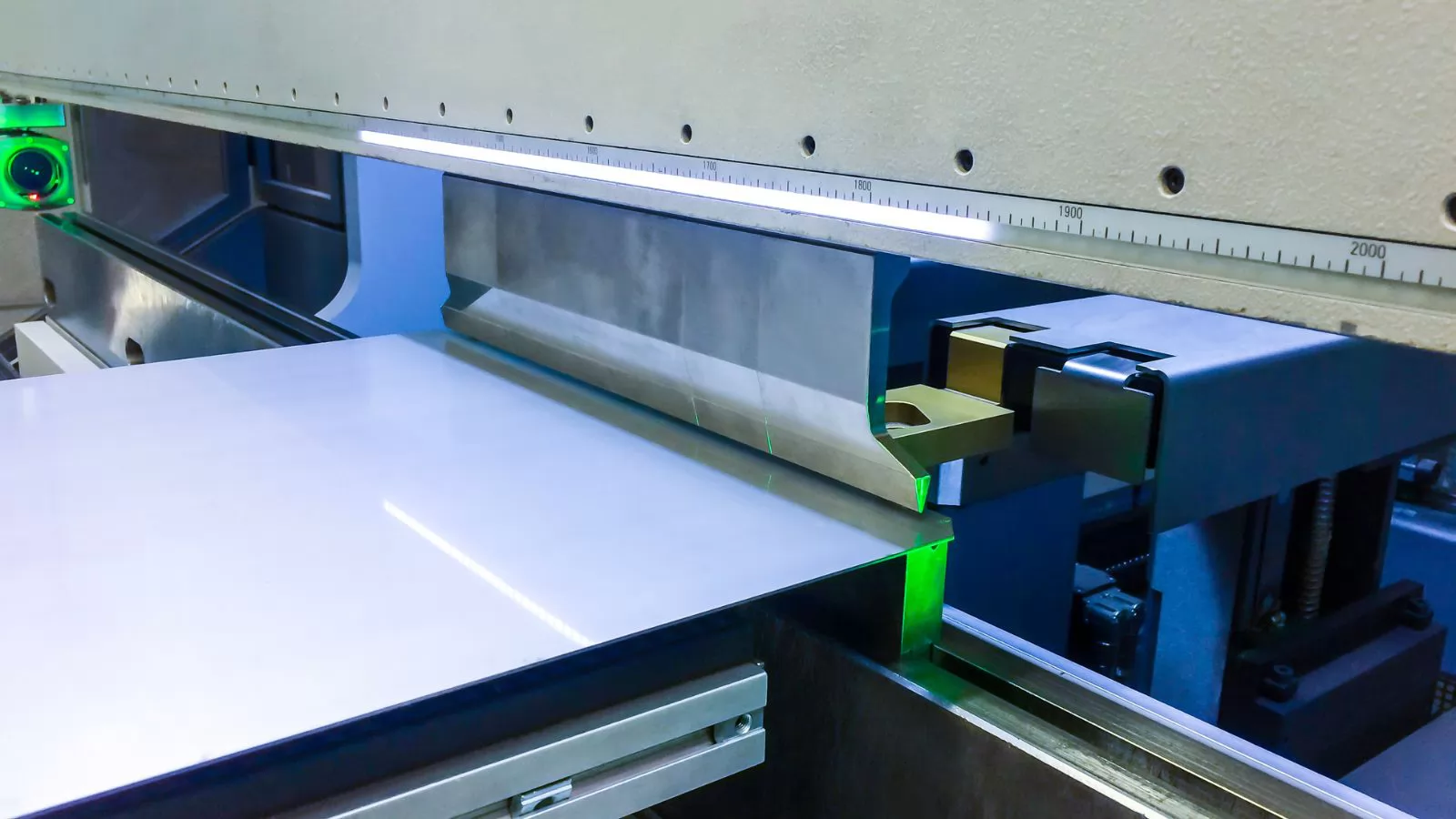

Precision and Repeatability for High-Quality Bends

Industries with strict tolerances rely on press brake precision and repeatability. Look for machines with accurate back gauge systems and stable frames. Top CNC press brake manufacturers design machines with minimal deflection, ensuring consistent results across large production batches.

CNC Control System: Smart, Fast, and Intuitive

Advanced CNC control systems streamline operation with touchscreen interfaces, offline programming, and 3D simulation. This allows for quicker setups, fewer errors, and operator-friendly usage. Choosing a machine with an upgraded controller boosts productivity and future automation integration.

Energy Efficiency and Drive Technology

Modern CNC press brakes use servo-electric or hybrid systems for reduced energy consumption. These energy-efficient drives lower operational costs while maintaining top performance. Trusted CNC press brake manufacturers integrate smart hydraulics to balance power and sustainability.

Automation-Ready Configuration

To meet growing production demands, opt for automation-ready press brakes. Features such as robotic arms, tool changers, and material handling systems enhance throughput. Reputable CNC press brake manufacturers provide flexible automation options that can be scaled over time.

When choosing CNC press brake manufacturers, prioritize reputation, advanced technology, and strong customer support. Look for suppliers with ISO certifications, proven industry experience, and innovative features like automated backgauges and hybrid systems that boost bending accuracy and efficiency. Top CNC press brake manufacturers also offer customization options—such as tailored tooling and integration with automation lines—to meet diverse production needs.

Reliable after-sales service, including technical support and maintenance, ensures long-term performance. Finally, strict quality control processes guarantee consistent precision and high-quality output for every bend.

Hydraulic CNC press brakes are widely used by manufacturers for their strong bending force and durability. Using hydraulic cylinders, these machines excel in heavy-duty applications, thick metals, and complex shapes. They're a reliable option when high pressure and consistent performance are essential in industrial settings.

Electric CNC press brakes, often recommended by CNC press brake manufacturers, offer energy savings and precise motion control. They use servo motors instead of hydraulic systems, delivering quieter, cleaner, and faster bending. These machines are ideal for precision sheet metal work and low-maintenance operations.

Leading CNC press brake manufacturers integrate robotics into automated CNC press brakes for enhanced efficiency. These systems streamline production, reduce labor costs, and ensure repeatable precision—making them perfect for high-volume operations and automated manufacturing environments requiring speed and consistency.

Manual CNC press brakes combine basic CNC controls with hands-on operation. Manufacturers recommend them for workshops handling small batches or custom work. Although less advanced, they still offer precision and flexibility, making them a cost-effective solution for low-volume metal fabrication tasks.

Some CNC press brake manufacturers develop specialized or custom CNC press brakes for unique bending needs—such as ultra-thin sheets, oversized components, or non-standard angles. These tailored machines deliver precision and adaptability, helping businesses meet niche production requirements with customized technology.

When selecting CNC press brake manufacturers, balancing the initial pricing with long-term value for money is crucial. The cost of a CNC press brake depends largely on factors like bending capacity, back gauge precision, and the type of drive system—whether hydraulic, electric, or servo-driven. While advanced automation features may increase the upfront investment, they enhance operational efficiency, reduce downtime, and lower maintenance expenses over the machine’s lifespan.

Choosing a trusted CNC press brake manufacturer ensures superior machine durability, reliable after-sales support, and a reduced total cost of ownership. Top-tier manufacturers also provide flexible financing solutions, enabling businesses to optimize their capital expenditure. Ultimately, investing in a quality CNC press brake delivers higher ROI and boosts overall production performance.

When choosing CNC press brake manufacturers, it's essential to assess their industry reputation, technological expertise, and quality of after-sales support. Leading CNC press brake suppliers deliver precision-engineered machines equipped with advanced control systems and customizable configurations tailored to various metal fabrication requirements. A trustworthy manufacturer guarantees long-term machine performance, energy efficiency, and consistent production accuracy, critical for meeting high-precision bending demands.

Moreover, comprehensive support services—including operator training, timely maintenance, and availability of spare parts—ensure smooth, uninterrupted operation. Selecting the right CNC press brake partner not only improves your manufacturing efficiency but also enhances your competitive advantage in the metalworking industry. Careful evaluation helps you invest in a machine that balances quality, cost, and service, ultimately driving better ROI and product quality.

Choosing the right CNC press brake manufacturer is essential for achieving superior machine precision, long-term durability, and reliable after-sales service. Top CNC press brake manufacturers prioritize these factors to help you maximize production efficiency and reduce downtime. By understanding key factors like bending capacity, control system quality, and brand reputation, you can make an informed investment in the ideal CNC press brake for your application.

Ready to enhance your manufacturing process? Contact trusted CNC press brake manufacturers today for expert advice and a customized quote.

.png)