Request a Quote

Request a Quote

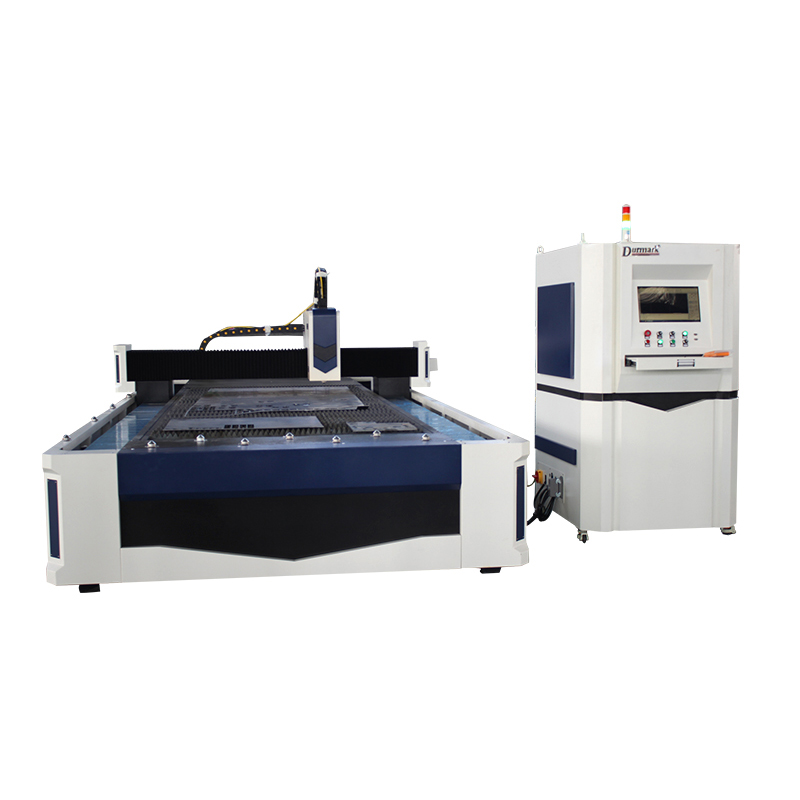

The fiber laser cutting machine uses the international advanced fiber laser to output high-energy and density laser beam, and focuses on the surface of the workpiece, so that the area on the workpiece irradiated by the ultra-fine focal spot melts and gasifies instantly, and the automatic cutting is realized by moving the spot irradiation position through the numerical control mechanical system. It is a high-tech equipment integrating advanced fiber laser technology, numerical control technology and precision machinery technology

Model | DLC-1530 / 1000w | |

CNC Control Unit | Cypcut CNC System | |

X axis (Rack & Pinion) | 3000 mm | |

Y axis (Rack & Pinion | 1500 mm | |

Z axis (Ball Screw) | 100 mm | |

Work piece dimensions | 1525 x 3050 mm | |

Rapid traverse (X and Y axis) | 105 m/min | |

Acceleration | 1.2G (12m/s2) | |

Vector speed | 108 m/min | |

Absolute positioning accuracy | ± 0.08 mm | |

Repeatability (X and Y axis) | ± 0.03 | |

Feed rat | Programmable up to 30 m/min | |

Programmable assist gases | Programmable assist gases C | |

Air | 0-6 Bar | |

Oxygen | 0-6 Bar | |

High Pressure | 0-25 Bar | |

Focusing lense | 5” ve 7. | |

Transfer tabl | Motorized - Automatic Exchan | |

Max. load capacity | 1550 | |

Fume extractor | 1000 m3/hour | |

Laser Cutting Head | RayTools from Switzerland | |

Laser Power | Raycus-1000w from China | |

Servo motor/ Servo drive | Mitsubishi from Japan's Brand | |

Motoreducer | SHIMPO from Japan's Brand | |

X ,Y-axis Rack | Gumgang from Japan's Brand | |

Liner Guid | HIWIN from TaiWan Brand | |

focus automatically, which is suitable for various focal

lengths without manual operation, convenient, fast and

accurate.

The same laser head can quickly change the focus lens with

different focal length, so as to meet the cutting of plates

with different thickness.

The dynamic operating range of Raycus’s low‐order‐mode kilowatt class fiber lasers is available from 10% to full power with no change in beam divergence or beam profile throughout the entire range. This allows a single laser to be utilized for both high and low‐power applications.

lenght processing lenses for vastly improved depth of field, less damage to optical components.

•Accuracy of S&A chiller for laser cooling +/‐ 1.0°C and for optic cooling +/‐ 0.5°C

•Water temperature stability for stable laser and best cutting quality

•Laser source ( Slabs), the cutting head are cooled by chiller

•Long consumable lifetime (lens, nozzle)

•Energy saving system