Request a Quote

Request a Quote

After the Spring Festival in 2025, the Durmark team visited the Turkish Machine Tool Exhibition. The cold texture of metal and the precise rhythm of mechanical operation interwove into a unique industrial aesthetic. This professional exhibition, centered on machine tool equipment and processing technology, was like a window, allowing me to gain insights into the cutting-edge developments and vigorous vitality in the mechanical manufacturing field in Turkey and even globally.

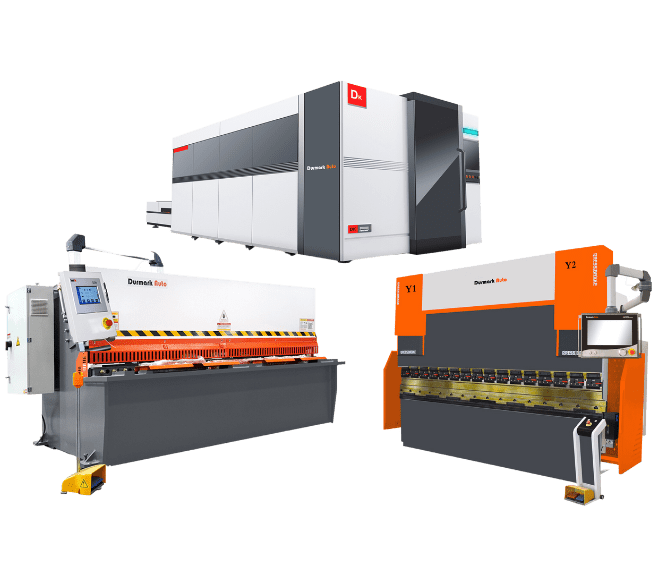

Inside the exhibition hall, all kinds of machine tools and equipment vie with each other in beauty, fully demonstrating the charm of industrial manufacturing. Among them, the display areas of Durmark shearing machines and bending machines are quite popular. High-precision CNC shearing machines demonstrate astonishing sheet metal cutting capabilities. Whether it is the slant-edge shearing machine that efficiently cuts sheets of different thicknesses with a relatively small shearing force, or the flat-edge shearing machine that achieves high-quality and low-distortion shearing effects with parallel blades, both showcase advanced technology. Specialized shearing machines for cold bending forming lines, steel structure production lines, sheet metal uncoiling lines, etc., closely meet the demands of industries such as automotive manufacturing, steel structure construction, and metal sheet processing. They precisely complete the shearing process, meeting the requirements of high-speed and continuous production. Their intelligent parameter adjustment and automated feeding and shearing processes significantly enhance production efficiency and reduce manual intervention.After the Spring Festival in 2025, the Durmark team visited the Turkish Machine Tool Exhibition. The cold texture of metal and the precise rhythm of mechanical operation interwove into a unique industrial aesthetic. This professional exhibition, centered on machine tool equipment and processing technology, was like a window, allowing me to gain insights into the cutting-edge developments and vigorous vitality in the mechanical manufacturing field in Turkey and even globally.

Inside the exhibition hall, all kinds of machine tools and equipment vie with each other in beauty, fully demonstrating the charm of industrial manufacturing. Among them, the display areas of Durmark shearing machines and bending machines are quite popular. High-precision CNC shearing machines demonstrate astonishing sheet metal cutting capabilities. Whether it is the slant-edge shearing machine that efficiently cuts sheets of different thicknesses with a relatively small shearing force, or the flat-edge shearing machine that achieves high-quality and low-distortion shearing effects with parallel blades, both showcase advanced technology. Specialized shearing machines for cold bending forming lines, steel structure production lines, sheet metal uncoiling lines, etc., closely meet the demands of industries such as automotive manufacturing, steel structure construction, and metal sheet processing. They precisely complete the shearing process, meeting the requirements of high-speed and continuous production. Their intelligent parameter adjustment and automated feeding and shearing processes significantly enhance production efficiency and reduce manual intervention.

The bending machine is no less impressive. Advanced CNC bending machines can precisely control the bending Angle, force and stroke, bending metal plates into various complex shapes, meeting the strict standards for high-precision bending of components in aerospace, electronic equipment and other industries. Especially the electro-hydraulic CNC bending machine, with the precise control of the electro-hydraulic servo system, achieves micron-level bending accuracy. The bent workpieces have extremely small Angle errors and superior surface quality. The new type of pure electric servo bending machine has integrated cutting-edge energy-saving technologies. Not only has its energy consumption been significantly reduced, but it has also achieved leaps in speed, accuracy and stability, flexibly meeting diverse bending demands. Some bending machines are also equipped with intelligent programming systems. Operators can input bending parameters through an intuitive human-machine interface, and the equipment can quickly plan the optimal bending path. The operation is simple and efficient, greatly reducing the production preparation time.

The strong professional exchange atmosphere at the exhibition site is equally inspiring. Exhibitors, industry experts and purchasers from all over the world gathered together to have in-depth discussions on technological innovations in machine tools such as shearing machines and bending machines, as well as the development trends of the industry. During the communication with representatives of local enterprises in Turkey, I learned that Turkey, with its superior geographical location and mature manufacturing foundation, holds an important position in the mechanical trade between Europe and Asia. The enthusiasm of local enterprises for exploring new technologies and their strong willingness to expand into the international market are impressive. In addition, the exhibition also features multiple technical seminars and new product launches. The cutting-edge technological concepts shared by experts and the innovative achievements showcased by enterprises have provided new ideas and directions for the industry's development. For instance, new tool materials have been applied to shearing machines and bending machines to enhance cutting and bending performance, and digital simulation technology has been utilized to optimize processing techniques. All have drawn a broad blueprint for the future development of shearing machines and bending machines.

Participating in the Turkish Machine Tool Exhibition this time is a learning journey of in-depth exploration in the field of mechanical manufacturing. It has made me deeply realize that under the wave of Industry 4.0 and intelligent manufacturing, shearing machines and bending machines are rapidly developing in the direction of high precision, intelligence, automation and energy conservation. At the same time, it also made me feel the importance of cooperation and exchange in the international mechanical manufacturing industry. Enterprises from different countries and regions learn from each other and achieve win-win cooperation through the exhibition platform, jointly promoting the progress of the global manufacturing industry. This experience has inspired me to keep a close eye on the technological trends in the industry in my future work, actively absorb advanced experiences, and contribute to enhancing the technological level in the field of mechanical manufacturing and promoting the development of the industry. Although this machine tool exhibition has come to an end, the precision and innovation it demonstrated will serve as the driving force for my continuous exploration and progress in the field of mechanical manufacturing

.png)