Request a Quote

Request a Quote

Sheet metal machinery refers to a wide range of specialized equipment used to cut, bend, form, and shape sheet metal into precise components for industrial applications. Commonly found in manufacturing, construction, and metal fabrication industries, these machines play a vital role in enhancing production efficiency and accuracy. Whether you're working with stainless steel, aluminum, or galvanized sheets, the right sheet metal machinery can significantly improve workflow and product quality.

In this guide, we’ll explore what sheet metal machinery is, its main types, and how it benefits modern fabrication. If you're a beginner or looking to invest in the right equipment, this article offers a complete overview tailored to your needs.

Sheet metal machinery refers to a range of industrial equipment used to cut, bend, punch, and shape sheet metal into desired forms for manufacturing and construction. These machines are essential in industries like automotive, aerospace, HVAC, and metal fabrication. Common types of sheet metal machinery include shearing machines, press brakes, punch presses, and CNC-controlled systems that offer high precision and efficiency.

Whether you're running a small workshop or a large-scale production facility, choosing the right sheet metal machinery can significantly improve productivity and quality. This guide will walk you through the basics, types, applications, and buying tips—perfect for beginners looking to understand what sheet metal machinery is and how to use it effectively.

Sheet metal machinery plays a crucial role in modern manufacturing by enabling fast, precise, and cost-effective metal fabrication. From automotive and aerospace to construction and electronics, industries rely on advanced sheet metal machinery to shape, cut, and form components with high accuracy. These machines not only improve production efficiency but also ensure consistency and quality in large-scale operations.

As automation and CNC technology evolve, sheet metal equipment becomes even more essential for competitive and sustainable manufacturing. Investing in reliable sheet metal machinery helps businesses meet tight deadlines, reduce waste, and enhance overall productivity.

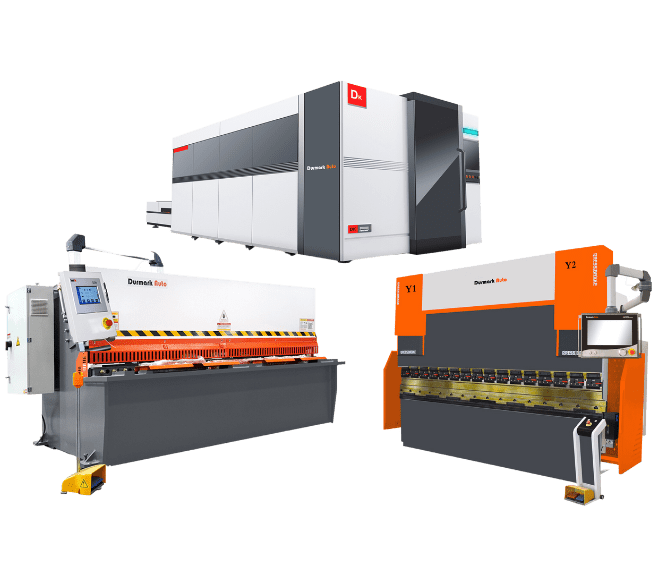

Shearing machines are essential sheet metal machinery used to cut large sheets into smaller sections. They deliver straight-line cuts without forming chips or using burning tools, making them ideal for basic metal cutting tasks in fabrication shops.

Press brakes are powerful sheet metal machines designed for bending metal sheets into desired angles. Whether it's V-bending or air bending, press brakes offer high precision, making them indispensable for forming operations in sheet metal processing.

Punch presses use a die and punch to shape or cut holes in sheet metal. This type of sheet metal machinery is perfect for repetitive stamping tasks and is widely used in the mass production of components like brackets or enclosures.

Roll forming machines continuously bend long strips of sheet metal into complex profiles. As a key player in high-volume production lines, this sheet metal machinery is known for producing consistent parts with minimal waste.

Laser cutting machines provide high-speed, precision cutting for various types of sheet metal. This advanced sheet metal machinery uses a focused laser beam to make intricate cuts, especially useful for detailed designs and thin materials.

Manual sheet metal machinery requires direct human control for every movement and adjustment. Operators need skill and experience to achieve consistent results. In contrast, CNC sheet metal machinery is computer-controlled, allowing for automated, highly accurate operations based on programmed instructions.

CNC sheet metal machines offer superior precision and repeatability compared to manual equipment. Once programmed, CNC machines can produce hundreds of identical parts with minimal variation, making them ideal for high-volume, tight-tolerance production.

Manual machines are slower and more labor-intensive. CNC sheet metal machinery significantly boosts productivity by automating complex operations and reducing cycle times. This makes CNC machines the better option for mass production and large-scale manufacturing.

CNC machines handle complex shapes and multi-step processes with ease, which is challenging for manual sheet metal machinery. They can switch between different parts and programs quickly, offering greater flexibility for custom or intricate metalworking tasks.

Manual sheet metal machines are less expensive upfront and suitable for small workshops or simple tasks. CNC sheet metal machinery, while costlier initially, provides long-term ROI through efficiency, reduced labor costs, and consistent high-quality output.

Choosing the right sheet metal machinery depends on several key factors, including the type of material you work with, its thickness, and your desired production volume. For high-precision projects, CNC sheet metal machines offer superior accuracy and automation. Smaller workshops may benefit from compact, multi-functional equipment, while large-scale factories often require heavy-duty press brakes or shearing machines.

Consider your budget, future scalability, and after-sales support when comparing different sheet metal equipment. Partnering with a reliable sheet metal machinery manufacturer ensures long-term performance and technical support. Evaluate machine specifications, application suitability, and energy efficiency before making a purchase.

Proper maintenance is essential to ensure the long-term performance and safety of your sheet metal machinery. Regularly inspect components for wear, clean machine surfaces, and lubricate moving parts to reduce friction and prevent breakdowns. For CNC sheet metal machines, check software updates and recalibrate systems periodically. Always follow the manufacturer's maintenance schedule and keep a detailed log of repairs.

Preventive care not only extends the lifespan of your equipment but also minimizes downtime and operational costs. Whether you operate a shearing machine, press brake, or punch press, investing in routine maintenance ensures reliable performance and optimal precision. For professional service or spare parts, consult your sheet metal machinery manufacturer.

The latest trends and innovations in sheet metal machinery are transforming the metal fabrication industry. Advancements like CNC automation, laser cutting technology, and smart machine integration are enhancing precision and efficiency in sheet metal processing. Modern sheet metal equipment now features improved energy-saving functions and user-friendly interfaces, enabling faster production with reduced errors.

Additionally, Industry 4.0 concepts are driving the adoption of connected machines that offer real-time monitoring and predictive maintenance. These innovations not only improve productivity but also extend the lifespan of sheet metal machines, making them more cost-effective for manufacturers. Staying updated with these trends is crucial for businesses seeking competitive advantages in metalworking and fabrication sectors.

Choosing the right sheet metal machinery is crucial for boosting your metal fabrication efficiency and product quality. Whether you are a beginner or an experienced professional, understanding the key features and applications of sheet metal equipment helps you make an informed decision. Investing in advanced, reliable sheet metal machines ensures precision, durability, and smooth operation for your projects.

Ready to take your manufacturing to the next level? Explore our expert guides and trusted product recommendations to find the best sheet metal machinery tailored to your needs. Contact us today to get personalized advice and start building with confidence!

.png)