Request a Quote

Request a Quote

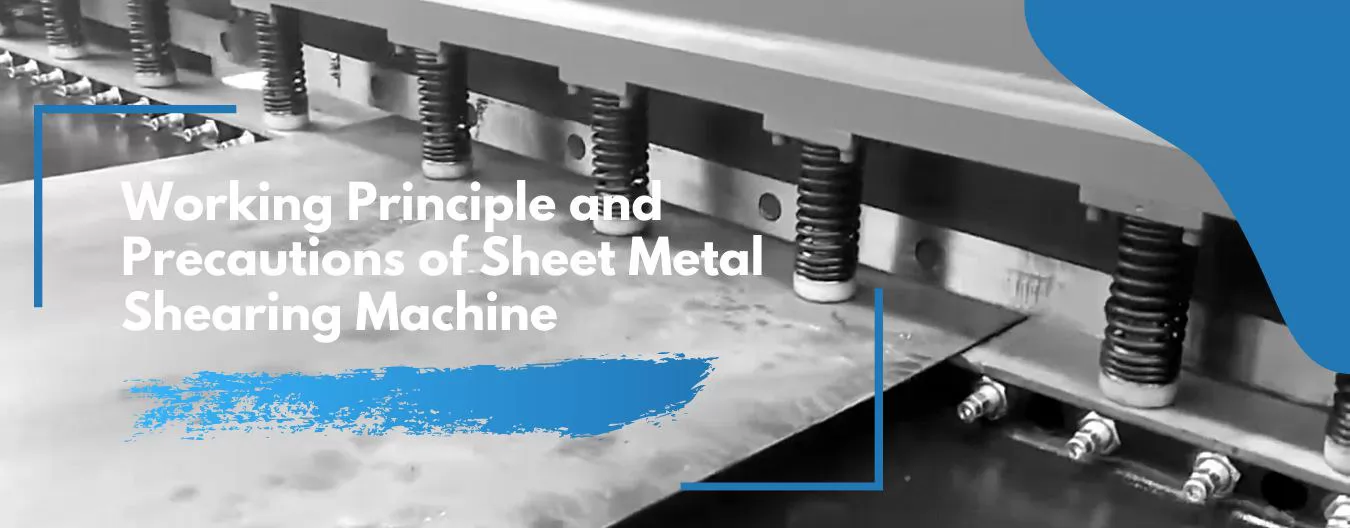

Sheet metal shearing machine is a kind of forging machinery. Its main function is the metal processing industry. It is a machine that uses one blade to perform reciprocating linear motion relative to another blade to cut sheet materials. It uses a moving upper blade and a fixed lower blade. Reasonable blade gap, applying a shearing force to various thicknesses of metal sheets, so that the sheets are separated according to the required size.

1. According to the power principle, it can be divided into mechanical shears and hydraulic shears.

The mechanical shearing machine adopts the resistance key form of clutch structure and open gear transmission and adopts more advanced electrical operation. The all-steel welding structure is simple, the operation is simple, the appearance is beautiful, and the energy consumption is low.

The hydraulic shearing machine has a beautiful appearance, excellent performance, and stable quality. It uses a moving upper blade and a fixed lower blade and uses a reasonable blade gap to apply shearing force to metal sheets of various thicknesses. The required size breaks apart.

2. According to the movement of the upper blade, it can be divided into swing shears and guillotine shears.

3. According to the operation mode, it can be divided into ordinary shearing machines and CNC shearing machines.

Ordinary shears are mechanical operations that need to be performed manually;

CNC shears generally use general-purpose or special-purpose computers to achieve digital program control, and they usually control mechanical quantities such as position, angle, and speed. The energy flows to the relevant switch. The production of CNC shears relies on the emergence of data carriers and binary data operations.

1. Start the shearing machine to work idling for several cycles to ensure that under normal conditions, test cuts of different thicknesses, from thin to thick.

2. Different blade gaps must be adjusted when trying to cut sheets of different thicknesses. If the corresponding blade gap is not adjusted, the durability of the blade will be affected.

3. Turn on the pressure gauge switch during the cutting process and observe the oil pressure value. The pressure should be less than 20MPa when cutting a 12mm plate.

4. There is noise during operation, stop and check

5. When the shearing machine is operating, the temperature of the fuel tank must be less than 60 degrees, and if it exceeds, shut down and rest.

.png)