Request a Quote

Request a Quote

Electric press brake manufacturers are transforming modern metal fabrication with precision, energy-efficient, and low-maintenance bending solutions. As more industries shift from traditional hydraulic to electric press brakes, choosing the right machine is vital for productivity and cost-efficiency. This 2025 expert guide to electric press brake manufacturers explores leading brands, compares electric vs. hydraulic vs. hybrid models, and analyzes CNC control systems, servo drives, and automation trends.

Whether you need high-speed bending, smart features, or sustainable performance, this detailed guide provides key insights, price comparisons, and a practical buying checklist to help you find the best electric press brake for your factory or workshop. Discover the future of sheet metal bending—read now and upgrade your production line.

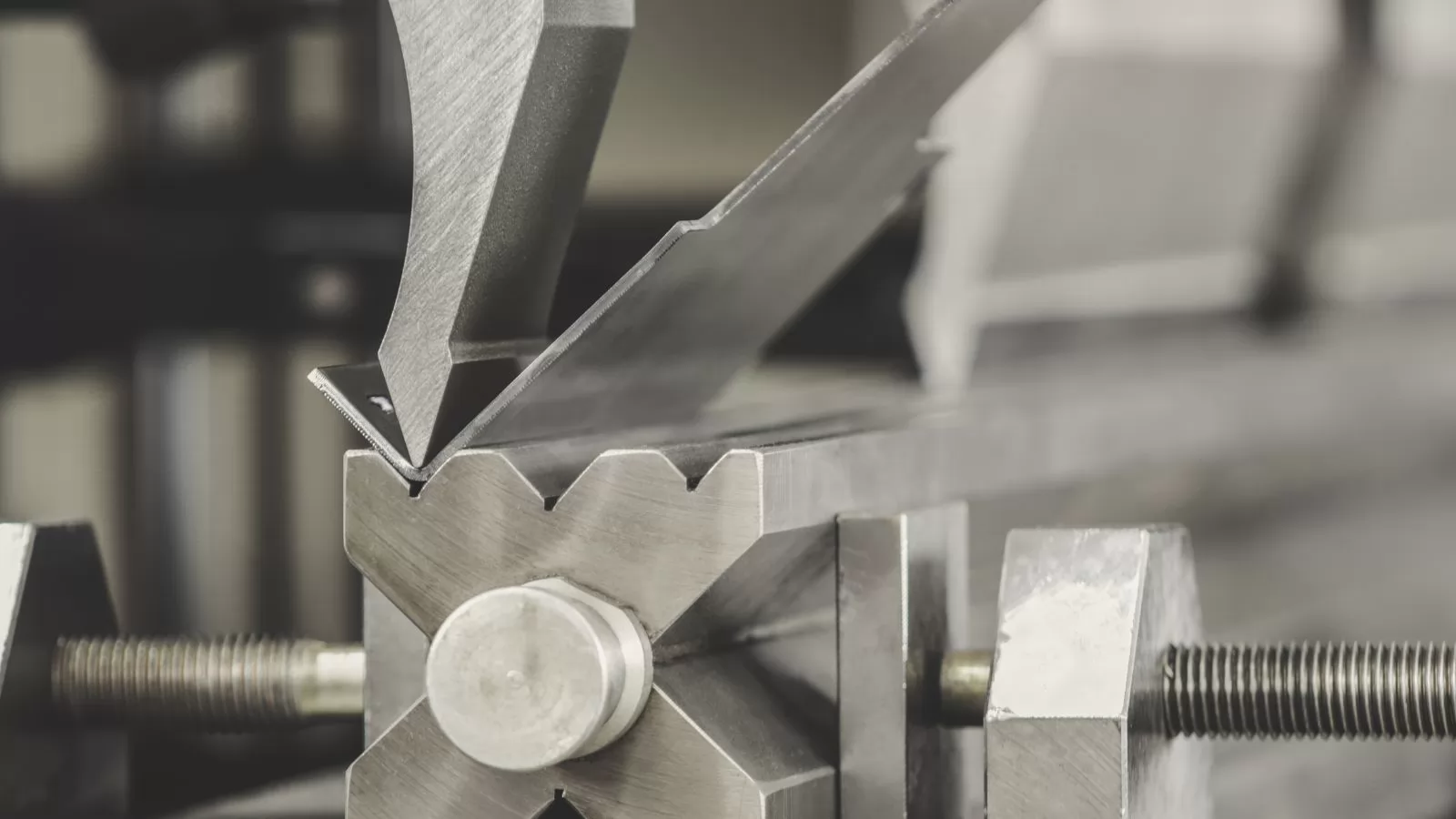

An electric press brake is a high-precision, energy-efficient bending machine powered by advanced servo motor technology instead of traditional hydraulic systems. Known for its superior bending accuracy, quieter operation, and lower energy consumption, it is ideal for modern metal fabrication and sheet metal bending applications.

Leading electric press brake manufacturers now incorporate intelligent CNC control systems, automated backgauges, and Industry 4.0 smart automation features to maximize production efficiency and reduce downtime. As the demand for sustainable, cost-effective CNC electric press brakes grows, manufacturers focus on delivering reliable machines that ensure consistent performance with minimal maintenance, perfect for industrial metalworking and fabrication shops.

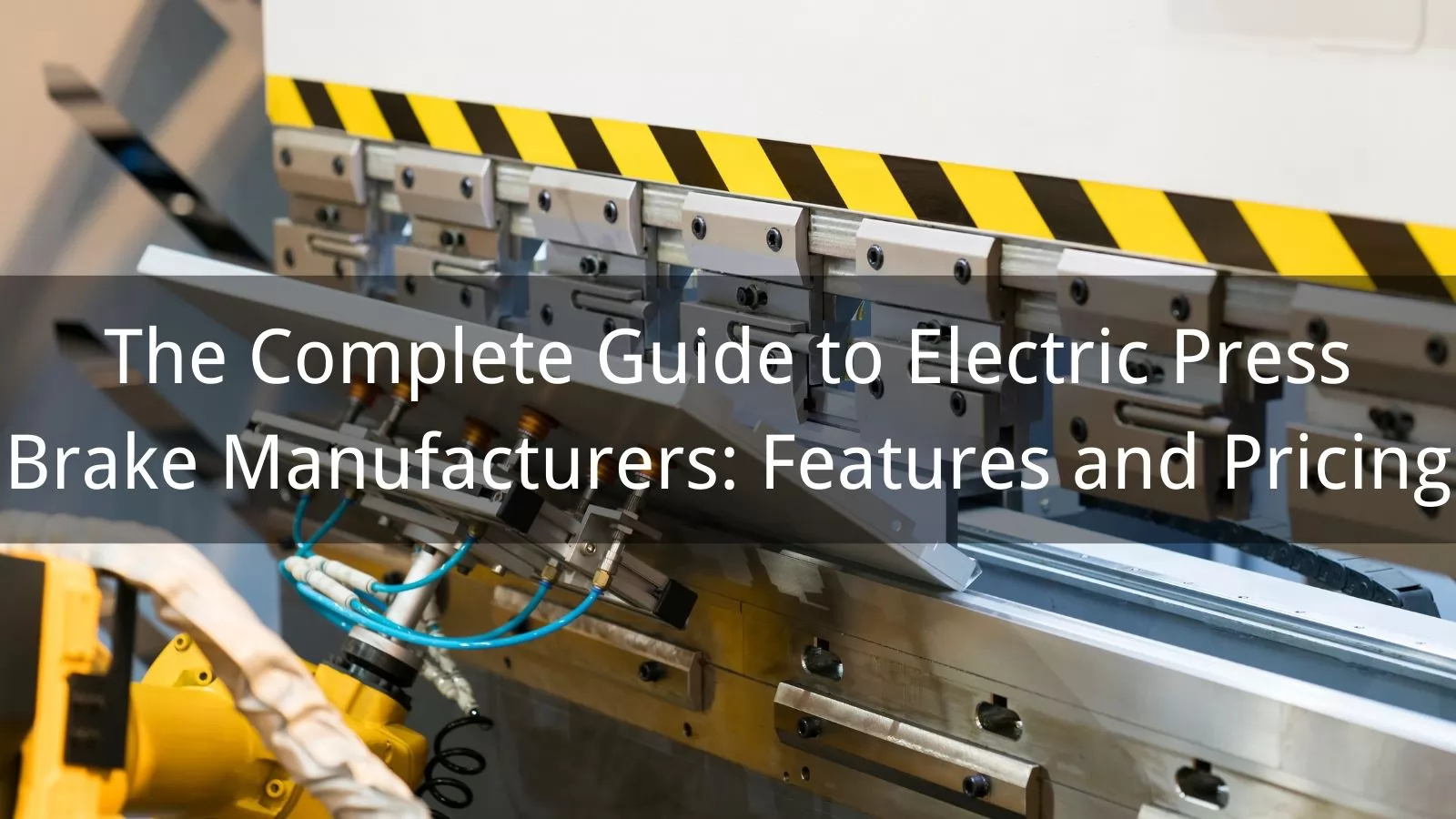

Electric press brakes equipped with advanced CNC controllers and servo motors ensure precise ram movement and consistent bending angles. These features are vital for industries requiring complex sheet metal fabrication, such as aerospace, electronics, and automotive sectors.

Servo-electric press brakes consume energy only during active operation, dramatically lowering power usage and environmental impact. Top electric press brake manufacturers highlight this benefit for sustainable, cost-effective metal processing in high-volume production environments.

Without hydraulic components, electric press brake machines eliminate issues like oil leakage and frequent part replacement. This results in reduced downtime and long-term reliability—ideal for continuous-duty applications in custom fabrication, appliance frames, and precision tools.

A modern CNC press brake offers interchangeable tooling systems, supporting a wide range of materials and thicknesses. This adaptability is essential for manufacturers in the construction, HVAC, and stainless-steel fabrication industries looking to expand product variety.

Top electric press brake manufacturers now offer automation features such as robotic bending cells, automatic tool changers, and backgauge programming. These innovations improve cycle times, cut labor costs, and support semi-automated or lights-out manufacturing.

Leading CNC press brakes include advanced safety systems like laser guarding, light curtains, and two-hand controls. These measures ensure safe, high-speed operations in critical industries such as shipbuilding, aerospace, and industrial machinery fabrication.

Wondering how much an electric press brake costs? In 2025, prices typically range from $50,000 for entry-level models to over $500,000 for advanced CNC electric press brakes equipped with servo motors, energy-efficient drives, and intelligent control systems. Several factors impact pricing—including tonnage capacity, bending length, automation features, and brand reputation. Leading electric press brake manufacturers now offer highly customized machines tailored to specific industrial applications. Investing in energy-efficient electric press brakes not only enhances precision and productivity but also lowers long-term operational costs.

To find the best value, compare quotes from top manufacturers and evaluate service, maintenance support, and upgrade options. Whether you're a small workshop or a large-scale factory, choosing the right press brake ensures maximum return on investment and consistent performance.

When choosing an electric press brake manufacturer, prioritize companies with extensive experience in CNC bending technology. Leading press brake brands often showcase ISO certifications, long-term customer partnerships, and case studies in automotive, appliance, or aerospace sectors. A proven reputation ensures machine reliability, stable performance, and trusted after-sales service.

Look closely at machine build quality, servo motor performance, and CNC controller accuracy. Top electric press brake manufacturers offer precision-driven systems that reduce energy consumption and ensure consistent bending angles. Compare specs like backgauge accuracy, stroke length, and bending force across models to match your specific production needs.

Select electric press brake manufacturers that provide customizable solutions for your production line. Modular machine designs and flexible tooling systems enable future upgrades in tonnage, automation, and bending complexity. This scalability helps your factory adapt to evolving manufacturing demands while reducing long-term capital expenditures.

A reliable after-sales support system is vital for minimizing downtime. Partner with press brake manufacturers that offer comprehensive service packages, remote diagnostics, and fast spare part availability. Strong technical support ensures quick troubleshooting, prolonged equipment lifespan, and smooth operation over the years.

Don’t just compare upfront prices—evaluate the total cost of ownership. High-quality electric press brakes often feature energy-saving servo systems and require less maintenance. Investing in a durable, efficient press brake enhances productivity, reduces power consumption, and delivers better ROI over its lifecycle.

Top electric press brake manufacturers are embracing Industry 4.0 by integrating IoT connectivity, real-time monitoring, and CNC automation to enhance precision and productivity. Smart features like predictive maintenance, remote diagnostics, and automatic tool changers are now standard, reducing downtime and labor costs.

As demand grows for energy-efficient and eco-friendly solutions, leading press brake suppliers are developing machines with low power consumption and high output. With flexible configurations and faster setup, modern electric press brakes are revolutionizing metal fabrication—making them essential in smart, sustainable manufacturing.

Choosing the right electric press brake manufacturer is essential for ensuring long-term reliability, precision, and high ROI. Top electric press brake manufacturers offer energy-efficient servo systems, advanced CNC controls, and superior bending accuracy—ideal for both small workshops and high-volume production. Compared to traditional hydraulic models, electric press brakes reduce operating costs while enhancing productivity and consistency. Whether you're upgrading your fabrication line or starting a new project, selecting a trusted manufacturer ensures top performance and future-ready automation.

Contact us today for expert guidance and a personalized quote tailored to your production needs.

.png)