Request a Quote

Request a Quote

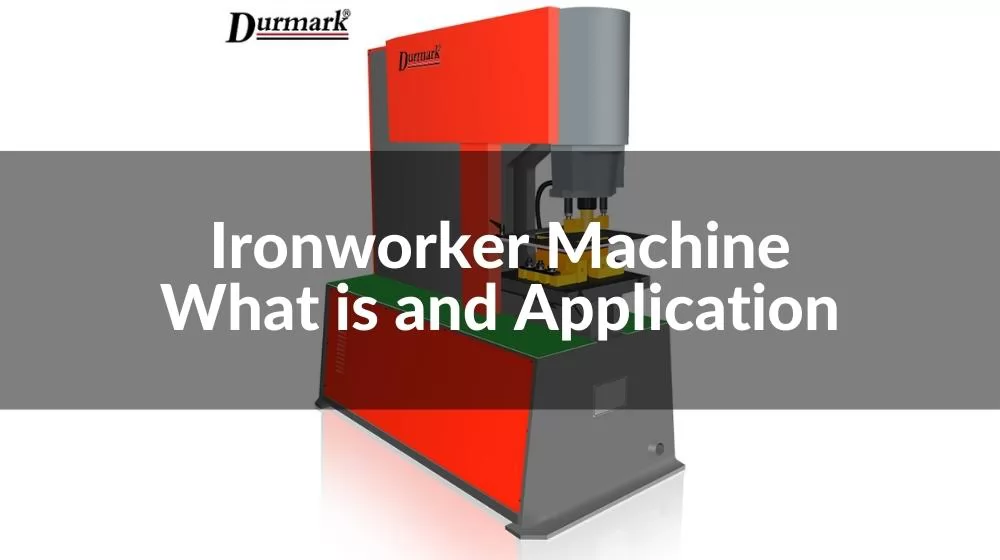

The Ironworker is a sturdy, versatile machine designed to handle the myriad jobs done by makers and manufacturers.

If you want to know or find a suitable ironworker machine, this article can guide you to get started quickly.

In this article, you will learn:

The Ironworker is a 3-in-1 machine that acts as a slotter, punch and shear.

The ironworker is an essential tool in any fabrication shop or fabrication facility because it can perform a variety of tasks without reworking. It helps save time, eliminate waste, increase productivity and create smooth holes and cuts.

It is a class of tools that use mechanical or hydraulic power to cut, slot, punch, form or bend metal by pressing a button or pulling a lever. They can be equipped with a variety of punches and dies to help you punch holes in steel or sheet metal. They are also often equipped with grooved sections to help you groove almost any machinable metal.

A conventional ironworker machine consists of a fixed frame, a motor, a safety shield, a metal workpiece, and a control panel/foot pedal. Most machines are electronically and/or hydraulically controlled, and some typical working principles include:

Slide with cutting edge for cutting metal material to a fixed edge.

Removable punch to create customizable holes in a variety of metal materials.

A plunger or sliding arm used to push metal products around a fixed point or into a mold.

The operator can perform most operations using a foot pedal or buttons, and many operations are often repeated in rapid succession for a stable production flow.

Due to the high force required to bend and cut metal, it is common on hydraulic ironwork machines.

Ironworker machine are widely used in:

Steel structure processing

Elevator and parts processing

Trailers: spare tire parts, trailer hinges, hitches, inserts and siding

Construction machinery industry: processing of belt conveyors and mixing plants

Agriculture and animal husbandry machinery industry: threshing frame, trailer body parts processing

Food industry machinery: slaughtering equipment frames and parts processing

High and low pressure tower parts processing

Wind power equipment: wind power tower climbing stairs, pedal parts processing

Processing of building embedded parts, conveyor brackets and other connecting parts

Grain machinery: Grain and oil equipment, starch equipment support, shell, small parts processing

Processing of railway wagons, automobiles and crane parts

Cutting, punching and bending of channel steel, square steel, round steel, H steel, I-beam and other steels

With ironwork, you can make smooth cuts and holes in sheet and steel, avoiding costly and time-consuming post-cutting operations. Setup is fast, operation is simple, and features are extensive.

Unlike other traditional methods that can take hours to set up for grooving, shearing and punching, sheet metal processing equipment reduces the work time required to process material by increasing the speed of operation and setup. They feature multiple workstations that allow you to move from one activity to the next without any time-consuming tool changes.

Since ironworking machines have different workstations and can be easily retrofitted to perform additional operations, they help reduce workload and in turn increase average output and output.

Unlike traditional punching, grooving and shearing techniques that generate a lot of waste due to human error, iron machining tools improve precision and efficiency by allowing operators to handle each punching, shearing, grooving and forming job up close, resulting in Help reduce waste

Reasonable maintenance of ironwork machines is an important means of saving production costs, and maintaining good maintenance habits can have a huge positive impact on the life of ironwork machines. We offer a few tips for maintaining your ironwork:

Strictly follow the operating procedures.

Regularly inspect and repair switches, fuses, and handles to ensure reliable operation.

Lubricate and scrub the machine 10 minutes before leaving get off work each day.

Add lubricating oil according to the requirements of the lubrication chart before each startup. The oil should be clean and free of deposits.

The shearing machine must be kept clean frequently, and the unpainted parts must be coated with anti-rust oil.

The lubricating oil in the motor bearing should be replaced and filled regularly, and the electrical parts should be checked regularly for normal, safe and reliable operation.

Frequently check whether the V-belt, handle, knob and button of the shearing machine are damaged. If the wear is serious, it should be replaced in time.

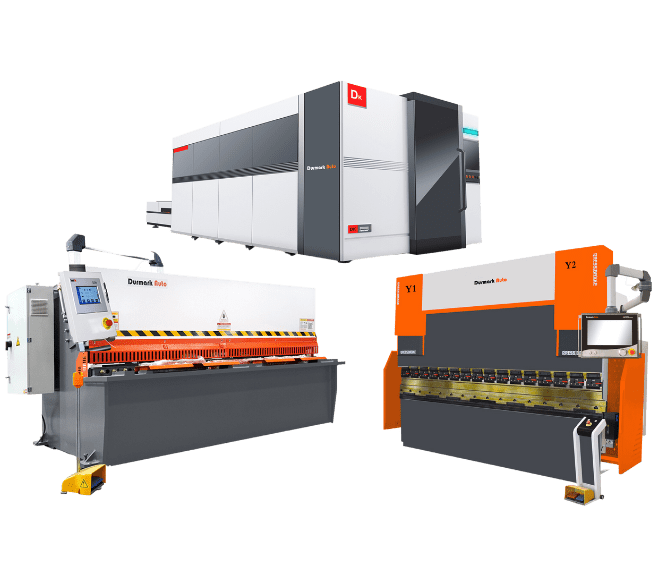

Durmark has been deeply involved in the metal processing machinery industry for many years and is a leading ironworking machinery manufacturer in China. We provide high-quality metal processing products to customers all over the world.

We provide a wide range of high-quality machined products, including press brakes, power presses, hydraulic presses, shearing machines, etc.

Read More:

What is a Shearing Machine? Working Principle and Application

Top 10 Press Brake Machine Manufacturers in 2022

China Top 10 Hydraulic Press Manufacturers 2022

Top 15 Ironworker Machine Manufacturers 2022

.png)