Request a Quote

Request a Quote

When it comes to metal fabrication, V-Grooving Machines are revolutionary devices that bring precision, versatility, and efficiency to the table. Whether you are in architectural fabrication or industrial manufacturing, understanding the types of V-Grooving Machines, their components, and their applications is crucial for making informed decisions. This guide aims to be your one-stop source for all things related to V-Grooving Machines.

Often regarded as a crucial tool in modern manufacturing, a V Grooving Machine precisely cuts narrow grooves without affecting the material's integrity. Think of it as the "surgeon" in your fabrication process: precise, efficient, and indispensable for specific tasks. This technology enables industries to produce highly specialized parts and components that meet exacting standards.

But why would one choose a V Grooving Machine over other machining methods? Well, one of its main advantages is the ability to maintain the original finish of the material being worked upon. No burn marks, no deformities—just a clean, precise groove that makes subsequent processes like bending a breeze.

Designed to operate with a level of precision that other machinery can seldom match, a V Grooving Machine is often the go-to equipment for industries where meticulous detailing and high-quality finish are required. Whether you're producing aerospace components or intricately designed architectural pieces, this machine ensures your end product is nothing short of exceptional.

A V Grooving Machine is more than just a sum of its parts; it's a finely tuned system where each component plays a critical role. Let's break down these components into two categories: Structural Elements and Functional Elements.

The frame and base are essentially the skeleton of the V Grooving Machine. Usually made of heavy-duty steel or a similar robust material, these elements provide the necessary rigidity and stability for precise operations.

The work table is where the material is placed for processing. Often designed to be adjustable, the work table ensures that different sizes of materials can be accommodated, allowing for a versatile range of projects.

The cutting head is the "heart" of the V Grooving Machine. Equipped with a specialized tool, usually a high-speed steel or carbide tip, the cutting head is responsible for creating the 'V' grooves in your material. The precision of the cutting head is paramount for achieving clean, exact grooves.

The drive mechanism is what propels the cutting head and other moving parts. Whether it's a belt-driven system or a more complex arrangement, the efficiency of the drive mechanism significantly impacts the machine's overall performance.

Last but not least, the controls and software serve as the "brain" of the V Grooving Machine. This could range from simple manual controls to advanced CNC (Computer Numerical Control) systems that offer high levels of automation and precision.

Understanding these basic components is essential for anyone considering investing in a V Grooving Machine, as it allows you to evaluate different models and make an informed decision that aligns with your specific requirements.

The V Grooving Machine comes in a variety of configurations to suit different needs and applications. In general, these machines can be categorized into three main types: Mechanical V Groovers, CNC V Groovers, and Hydraulic V Groovers. Each comes with its own set of features, advantages, and limitations. Let's dig a little deeper to find out which might be the best fit for your operations.

Mechanical V Groovers are often the most basic but also the most durable types. These are generally more manual in nature and require an operator to adjust settings like depth and angle. Because of their simplicity, they are usually less expensive but may not offer the level of precision and automation that some industries require.

CNC (Computer Numerical Control) V Groovers represent the pinnacle of technology in this sector. These machines offer the highest level of precision and consistency, thanks to their computerized controls. Suitable for high-volume production, they can store multiple program settings, dramatically reducing setup times. However, this sophistication comes at a price, making them generally more expensive than other types.

Hydraulic V Groovers use hydraulic systems to power the cutting head and are known for their robust performance and durability. They offer a balanced mix of manual and automated features, allowing for a fair amount of customization while still benefiting from the power and efficiency that hydraulic systems provide. They are often the go-to choice for medium-scale operations.

If you've ever wondered how a V Grooving Machine turns a flat sheet of material into a pliable form with precise grooves, you're in for a treat. In essence, these machines operate on a few basic principles that allow for that high level of precision and quality in the end product. Let's unpack those principles.

At the heart of the operation is the cutting head, a component we touched on in an earlier chapter. This cutting head is mounted onto a drive mechanism that moves it along predefined paths. The cutting head lowers itself onto the material on the work table, and as it moves, it cuts a 'V' shaped groove into the material. The depth, angle, and length of the groove are determined by the machine settings, which can be manually adjusted or programmed in the case of CNC V Groovers.

The material to be grooved is placed on the work table. In many models, the work table moves the material horizontally while the cutting head remains stationary. This ensures that the material is fed consistently into the cutting zone, resulting in even and precise grooves.

Control systems, either manual or computerized, dictate the actions of both the cutting head and the work table. In CNC V Groovers, for example, the computerized control enables highly complex grooving patterns to be executed with minimal human intervention. This allows for high precision and repeatability, which are crucial in many industrial applications.

The V Grooving Machine isn't a one-trick pony; it has a myriad of applications across multiple industries. From architectural wonders to high-performance cars, V Grooving plays a pivotal role in various forms of fabrication and assembly. Let's look at some of these applications in detail.

While V Grooving Machines are commonly found in metal fabrication shops, their versatility means they are also used in woodwork, plastics, and even the aerospace industry. Their main function remains the same—creating precise 'V' shaped grooves in a material—but the end-use of these grooves can vary widely.

In the world of architecture, V Grooving is often used for paneling and cladding. Think of those aesthetically pleasing facades on modern buildings or intricately designed interiors. V Grooving machines provide the kind of precision required to ensure that these panels fit together seamlessly, giving architects more freedom to be creative with their designs.

In industrial settings, V Grooving Machines are employed for a variety of tasks like preparing metal sheets for welding or creating grooves in pipes and conduits. Their ability to handle large volumes while maintaining high precision makes them invaluable in mass production scenarios.

The automotive industry is another significant consumer of V Grooved parts. Whether it's in the bodywork of cars or the construction of specialized automotive components, V Grooving offers the exactitude needed in this highly competitive and precision-oriented field.

6: How to Choose the Right V-Grooving Machine

Selecting the ideal V Grooving Machine for your specific application can feel like an overwhelming task. With different types and features available, how do you know which one is the best fit? Well, worry not. This chapter is designed to guide you through the key considerations you should have in mind when making your decision.

As we explored earlier, there are various types of V Grooving Machines—Mechanical, CNC, and Hydraulic. Your choice will depend on the volume and complexity of the work you have. For instance, CNC machines are ideal for more intricate designs, while Hydraulic versions are often better suited for heavy-duty tasks.

Different machines are designed to handle different materials. Whether you're working with metal, wood, or plastic, ensure that the machine you select is well-suited for your specific material. This could affect the machine’s longevity and the quality of the grooves.

The precision and speed of the machine are vital in maintaining efficiency and quality. Look for a machine that has a good balance between the two to meet your production needs.

Obviously, budget plays a huge role in your choice. V Grooving Machines can be quite an investment. Therefore, you need to balance your financial constraints with the features and benefits offered by the machine.

Lastly, consider the after-sales service, including the warranty and customer support. A machine is a long-term investment, and having robust support can save you time, money, and headaches in the long run.

Choosing a V-Grooving Machine is only half the battle. The other crucial aspect is choosing the right manufacturer. The quality of the machine, the after-sales support, and the reputation of the manufacturer—all these play a key role in ensuring your investment is sound. Here are some guidelines to help you make the right choice.

When it comes to machinery, experience matters. Look for a manufacturer with a track record of reliability and quality. Reviews and testimonials can give you some insights, but don't hesitate to ask for references or case studies that demonstrate their expertise.

The longevity and performance of your V-Grooving Machine will depend on the quality of materials used. Make sure that the manufacturer adheres to international standards and quality control processes.

Depending on your needs, you may require customization options, whether that's in terms of machine dimensions, additional features, or software capabilities. Check if the manufacturer is flexible enough to accommodate such requirements.

Good technical support can be a lifesaver when you encounter issues. A reliable manufacturer should offer robust customer service along with a solid warranty that will give you peace of mind.

While price is an important consideration, it shouldn't be the only one. Sometimes, going for the cheapest option can end up costing you more in the long run due to maintenance issues or poor performance. Always weigh the value you're getting against the price you're paying.

We hope this comprehensive guide has equipped you with the knowledge you need about V-Grooving Machines—their types, essential components, working principles, and diverse applications. Making the right choice begins with having the right information, and we trust this guide has served that purpose.

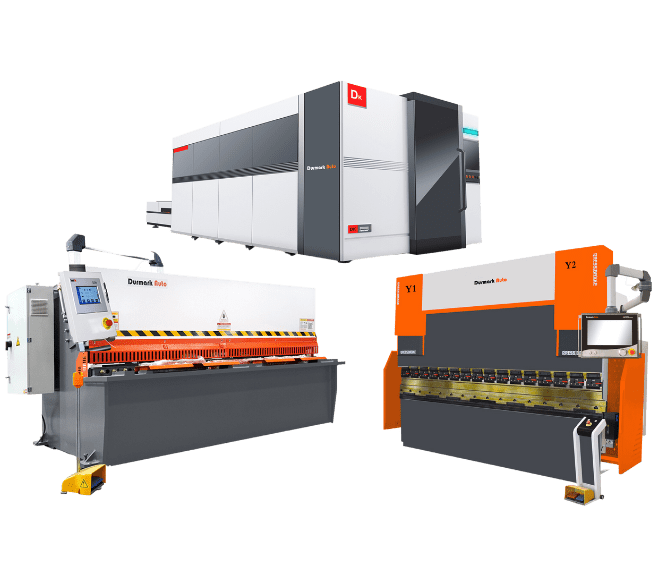

For top-notch V-Grooving Machines, look no further than Durmark. With a solid reputation for excellence, Durmark is a manufacturer you can trust for both quality and reliability. To learn more about our range of V-Grooving Machines and other offerings, visit our website at www.durmark-machinery.com.

In this section, we'll answer some of the most frequently asked questions about V-Grooving Machines. Whether you're a seasoned user or a newcomer, these FAQs should clear up any lingering questions or concerns you may have.

Safety should always be a top priority when operating any kind of machinery, and V-Grooving Machines are no exception. Risks generally involve moving parts that could cause injury if not handled correctly, electrical components that pose a shock risk, and heavy materials that could lead to strain or injury during loading and unloading. Always consult the safety manual and adhere to the manufacturer's guidelines to mitigate these risks.

At a glance, V-Grooving Machines and standard sheet metal machines may seem similar, but they serve distinct purposes. A V-Grooving Machine is specialized for creating grooves in materials, usually metal sheets, to facilitate bending or joining. Standard sheet metal machines, on the other hand, may include a broader set of functions like cutting, shaping, and joining, but often lack the precision grooving capabilities that a V-Grooving Machine offers.

If you have any more questions or need further clarification on any topic discussed in this guide, don't hesitate to reach out to our customer support team. Your satisfaction and understanding are our primary goals.

Read More:

Top 10 Shearing Machine Manufacturer in 2022

How to Choose a Right Shearing Machine Manufacturer

.png)